Folder Resistance Welding

As a leader in the resistance welding cable and accessory field, Flex-Cable is a major supplier to the global automobile industry and holds a strong presence with Original Equipment Manufacturers (OEM) in the appliance, electronic, and consumer related product industries.

In today’s world of rapid growth and high technology, where a product can be here today and gone tomorrow; service, quality and technology are the key assets which separate the few from the many. For more than 55 years, Flex-Cable has developed these assets in order to be recognized as a leader in Resistance Welding Cable technology.

Flex-Cable offers exceptional design, assembly and energy. Our Resistance Welding Cables are low maintenance and provide a longer cable life. Size for size, the conductor arrangement gives approximately 10% more current for a given applied voltage than other available cable types.

Flex-Cable Resistance Welding Cables are created in one of two ways.

The Standards Process

Patented process with a six rope alternate polarity utilizing a unique, low wear point wire rope design. Providing the lowest inductive reactance and lowest impedance with the highest electrical power factor of all cables in today’s market place. The positive cooling paths maximize thermal efficiency and special water passageways reduce terminal heating.

Color-Flex Resistance Welding Cable

The Color-Flex Resistance Welding Cable jacket is made up of a specially formulated, six layer, natural rubber compound with an abrasion resistant bumper as an integral part of the jacket, making it completely durable to overcome distress and flexure.

Complex Resistance Welding Cable

Available in both Standard and Flex-cel Process, these Resistance Welding Cables are made of specially designed rubber jacketing with ergonomics in mind, offering individually wrapped internal copper ropes with a perforated protective sleeve, which would improve water flow, decrease operating temperature and improve flexibility.

The Flex-cel Process

State-of-the-art, patent-pending process which incorporates a specially extruded ethylene propylene diene monomer rubber material covering each individual conductor rope within the cable. Then punched with symmetrical cooling channels to capture and isolate broken strands of copper wire to prevent cooling system contamination and obstructed water flow. Vortex water flow action causes increased heat transfer, resulting in higher cooling efficiency. The concept occupies less volume than standard separator cables resulting in increased flexibility as well as additional water volume to alleviate heat.

American Power Resistance Welding Cable

Combined with proper dress out and a good preventative maintenance program, this Resistance Welding Cable will virtually eliminate down time. The interior construction and outer hose make this cable a hard worker and a true value.

Euro-Flex Resistance Welding Cable

These Resistance Welding Cables have a rugged urethane outer jacket allowing for the combined advantage of safety, abrasion-resistance and long cable life into one unique design. Perforations and flow space between the wire and material create a sufficient Thermally Forced Cooling System.

Categories

Folder Air Cooled Cables

Air Cooled Jumper designs use an innovative stranding of wire which allows cables to be bent, twisted, looped or curled under static or dynamic loading. Terminals are swaged-formed and flared on each end to relieve stress. Available in individually wrapped and loose fitting cover designs.

Color-Flex Air Cooled Cable

These jumpers are extra flexible cable rope-type secondary conductors (0.010 inch strands) featuring silver plated connectors swedge-formed on each end. Standard air cooled jumpers are encased in a loose fitting, non-flammable, neoprene impregnated sheath to provide abrasion protection, flexibility and cooling. Color coded for easy identification. Save time in replacement by easily matching the color and identifying the length.

Flex-Tra Air Cooled Cable

These jumpers were developed to allow freedom in design for today’s automotive and robotic welding applications. Flex-Tra utilizes a unique wound wire which allows that cable to bend, twist, loop and curl under static or dynamic loading. The optional perforated cover enhances flexibility and allows for greater cooling, adding to service life.

IW-Flex Air Cooled Cable

This individually wrapped jumper cable is engineered for special applications and flexibility. Advancements include:

▶ Each rope is individually insulated

▶ Increased flexibility and versatility

▶ Improved insulation method does not require standard hose cover

▶ Eliminates frictional wear between adjacent ropes

▶ Reduces strand failure at rear of terminal

Folder Kickless Cables

Kickless Cables are flexible, low-maintenance cables offering a longer cable life. Magnetic stresses are essentially eliminated with our six conductor design. Bend and twist are enhanced. Size for size, the conductor arrangement gives approximately 10% more current for a given applied voltage than other available cable types.

Color-Flex Kickless Cable

Standard cable for typical robotic applications. The outside hose has a durable rubber blend outer covering which gives good support for the cable while allowing the cable to bend and twist.

American Power Kickless Cable

The best solution for applications that perform many tight bends and twists. The jacket construction is the same as Color-Flex, while the interior construction is Flex-cel, giving good support and resisting abrasion. While improving flex life, cooling channels trap broken wire strands and prevent plugged water ports.

Euro-Flex Kickless Cable

The best cable for high abrasion situations. This cable has all the benefits of the American Power Cable with the addition of a Polyurethane outer layer on the jacket. Euro-Flex combines all of the advantages of a reinforced rubber hose with the abrasion resistance of urethane and a durable interior creating the highest performing cable ever.

Complex Kickless Cable

The cables excellent ability to bend and twist reduces the ergonomic stress on the gun operator while maintaining the safety of a reinforced rubber tube inside.

Folder Military Welding Cables

Flex-Cable is also a manufacturer of custom Military and Aerospace welding cables. These heavy-duty cables offer a military strength option for the resistance welding market.

With American-made products and intimate, personalized attention, Flex-Cable supports the American military with quality cables and distinguished service throughout all branches.

Our Direct Support Electrical Test System Adapter offers the strongest weld for military robots.

Folder Primary Cables

Flex-Cable's Prime-Link Systems offers a full variety of your Primary Cable needs.

Standard Primary Cable Connections

These connectors are specially designed and manufactured for maximum flex life. Every Prime-Link connector is molded to the cable and incorporates a Strain Relief for extra durability and longer cable life. Our innovative and consistent processing results in unparalleled performance.

▶ All Prime-Link cable ends are straight, the 90⁰ is accomplished by the mounted connection

▶ The Prime-Link coupling provides a fast, yet secure, motionless connection

▶ The coupling ring is attached to the connector by a lanyard for safety and convenience

Mounted Primary Cable Connections

Specially designed and manufactured to simplify your high current connections. Our innovative and consistent processing results in unparalleled performance.

▶ All Prime-Link cable ends are straight, the 90⁰ is accomplished by the mounted connection

▶ The Prime-Link coupling provides a fast, yet secure, motionless connection

▶ The coupling ring is attached to the connector by a lanyard for safety and convenience

Primary Cable Strain Relief: Boots & Booties

Strain reliefs extend cable life and reinforce the connection to equipment. A strain relief is attached to a cable or cable assembly and is designed to increase the bend radius and absorb the mechanical forces exerted during use.

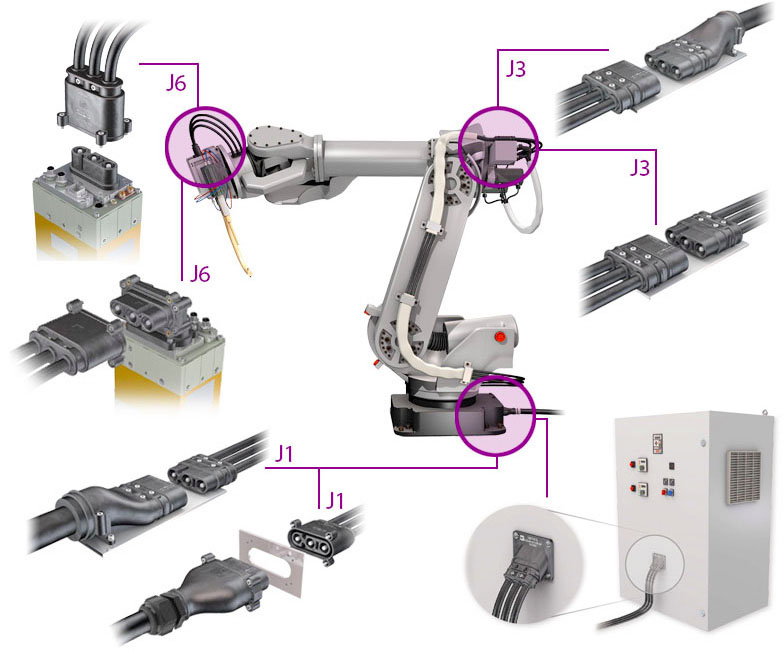

Folder RobiFix Multi-Contact Cables

Flex-Cable also offers a complete and tailored line of RobiFix Multi-Contact cables for the resistance welding marketing.

These cable are highly reliable, cost-effective and space-saving which means of integrating power supplies in robotic dress packs and running them along robotic arms. This latest innovation does not require any special assembly tools; the insertion into and removal from the connector housing couldn’t be any easier. The insulating material is resistant to spattering, sparking and welding vapors.

RobiFix Multi-Contact Cables are the smart solution. This new concept for primary power supply on welding robots offers:

▶ Quick disconnect solutions for minimized downtime

▶ Compact and modular design with superior performance

▶ Light weight ideal for down-sizing purposes

▶ Fast integration and easy maintenance

▶ Dependable with high-current capacity

▶ Total cost reduction about 50%

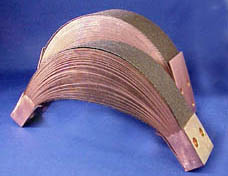

Folder Shunts

Offering many sizes and configurations of shunts tailored to our customers needs, Flex-Cable has recognized the importance of engineering new concepts and improving technology in the shunt market. Flex-Cable’s resistance welded shunts improve electrical and mechanical properties in comparison to conventionally welded or riveted shunts. The individual copper strips of the shunts are fused, assuring minimal resistance and operation temperature which increases product life and reduces downtime.

Flex-Cable's new molecular fused process, along with a tin plated process, offers the following advantages to the resistance welding market overall:

▶ Extra lubricity between the leaves.

▶ Long term corrosion protection of the leaves.

▶ Low temperature joining process. No

fired molecular annealing of the leaves.

▶ Near perfect joint resistance. Combined joint resistance typically less than 1/2 micro ohm.

▶ Long shelf life resulting from low temperature jointing process, which seals out corrosion. Low resistance is maintained throughout the life of the shunt.

▶ Improved appearance.

▶ Eliminates the toxic hazard of lead in a soldered joint.

▶ Computer controlled process gives optimum blousing.

Flex-Cable's shunts are fused with high conductivity and offer an optional silver plating on contact surfaces and Teflon jacket available for improved wear and tear, insulation and protection.

Shunt materials available:

▶ Half-hard

▶ Dead soft

▶ Combination

▶ Any of the above with “Hi-Life” TFE coating

Folder Water Cooled Cables

Flex-Cable's water cooled cable is a significant step towards increased cable life and reduced downtime. The new design provides a flared strain relief for the wire while at the same time eliminating the possibility of solder wicking.

Color-Flex Water Cooled Cable

Standard cable for typical robotic applications. This cable offers good support while allowing the cable to bend and twist. Made of polyester tire cord for durability.

American Power Water Cooled Cable

The step up from Color-Flex, this is the best solution for applications that perform many tight bends and twists. Constructed the Flex-cel way, this cable gives good support and resists abrasion. While improving flexibility, the cooling channels trap broken wire strands and prevent plugged water ports.

Euro-Flex Water Cooled Cable

This cable can handle high abrasion situations with a Polyurethane outer layer on the jacket. Euro-Flex combines a durable interior with a durable exterior creating the highest performing cable ever.

Complex Water Cooled Cable

This cables ability for extreme bends and twists reduces the ergonomic stress on the gun operator and maintains safety with a reinforced rubber tube inside.